8 Important Factors Should Be Considered When Buying Aircraft Parts

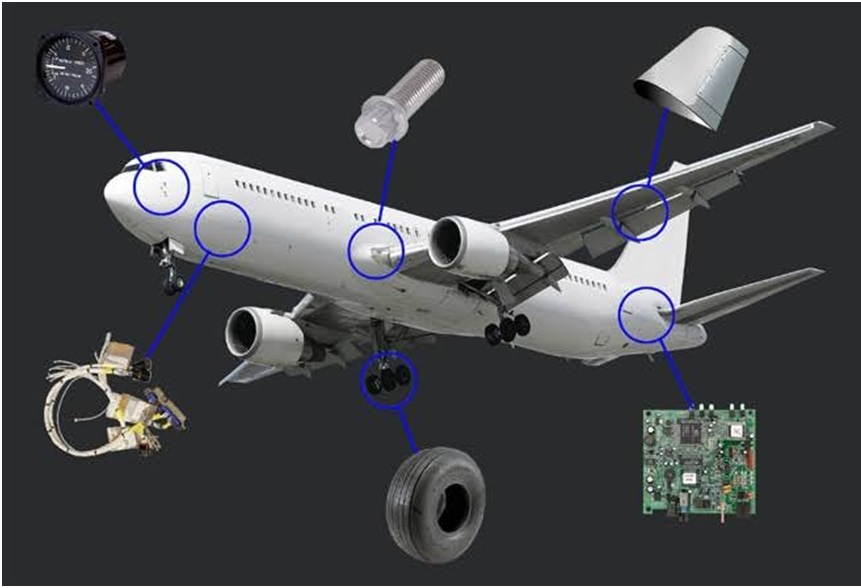

Engineering an aircraft is a complex process, and before you set out to buy the aircraft parts, you need to consider certain factors. Aircraft components have evolved significantly in the past century. It has made flights more efficient, safer, and faster. There are essentially five main components of an aircraft, fuselage, wings, empennage, power plant, and landing gear.

The fuselage is an aircraft’s main body section that holds crew, passengers, and cargo. Aircraft wings are a fin-like structure that produces lift while moving through air or some other fluid. The empennage is the rear part of an aircraft, and it provides stability during flight. Power craft in a plane is a mounted gas turbine engine that generates air to power the air turbine starter(s). The engine and propeller make up the power plant. The landing gear is the undercarriage of an aircraft used for either takeoff or landing. Shock absorbers and wheels are part of the landing gear.

These are the major components of an aircraft. If you want to manufacture or repair your plane, you need to understand the various parts’ dynamics. You can purchase aircraft parts online as most reliable aircraft hardware companies have an e-commerce platform to sell aircraft parts online.

Before you purchase aircraft parts, you need to consider the following points.

-

Identify What You Require

You need to assess your project needs and determine the exact items that you need. Different types of aircraft hardware are available in the marketplace. Based on the operating that you need to carry out, be it manufacturing, repair/refurbishment, you need to identify the part you need. Some of the standard necessary hardware parts you may require are bolts, washers, screws, rivets, fasteners, cotton pins, and safety wires, among other types. Evaluate your plan thoroughly to determine the exact item you need to use.

-

Consider Your Sources

To select the right vendor, you need to ascertain if they can offer timely delivery, warranty, and reliable after-sales services. Some of the most common types of vendors or distributors selling aeroplane parts:

o OEM: The original equipment manufacturers offer spare parts for all kinds of aircraft models. They provide certainty and manufacture industry-standard components. OEM parts are new, and they often come with a warranty.

o Distributor: There are mainly two types of distributors who sell aircraft parts, i.e., general and OEM-authorised distributors.

-

Research About Your Supplier

Carefully assess the inventory of the supplier before you make your purchase. Ensure that your vendor has ratings/references from current and prior customers. You can also approach the customers online and ask them for feedback about the company. Choose a company that has substantial years of experience in supplying aircraft hardware components.

-

Part Number

It is crucial to purchase the correct parts. You should check the aircraft’s catalog, identify the serial number, model and type. Accordingly, ask your supplier if the necessary details with the correct configuration are available. The price of the part depends on the modifications or upgrades that the manufacturer introduces to the components.

-

Certification

Choose a supplier who can produce certifications to ensure that the aircraft parts are of high quality and will remain functional for the long term. You need to assess various information such as OEM details, inspection date, condition of the part, and certified professionals’ authentic signatures. Certain factors have dual Certification, namely EASA Form 1 and FAA Form 8130.

-

Use Of Materials

You need to consider the quality, specifications, and configurations of the material used to manufacture the aircraft parts. You have specific types of materials to consider when choosing the hardware components. Look for items made out of aluminum alloy, titanium, and stainless steel. These materials guarantee longevity and minimize the risk of failure or any downtime issues.

-

Look For Aircraft-Grade

It would help if you looked for aircraft grades and not the commercial ones. The industrial categories are suitable for testing, whereas the plane grades are ideal for accurate installation. The commercial ones may have lower quality standards and price compared to the aeroplane grades. Any compromise with the quality of the components can put your aircraft to risk. Hence, ensuring the quality is necessary before you buy aircraft parts.

-

Outsource Installation

You can outsource the installation of the items to an experienced service agency that specializes in building. Plane owners cannot manage to install every hardware of their planes. Some of the installation processes are pretty complex. Seeking professional intervention helps to achieve quality outcomes. Know your outsourcing strategy, and choose an agent who specializes in this kind of service solution.

To Conclude:

Aeroplane supplies have specific measurements, and before you make your purchase make sure that it matches with the manufacturers’ specification. Ensure that the vendor has the necessary certifications before you purchase aircraft parts. Also, make sure that the vendor has substantial experience in this field. You can outsource the installation of parts to a qualified professional for better service.