Benefits of Hiring a Professional Prototype Machining Company

Manual machinery has been replaced by CNC precision metal cutting machines and designers are celebrating all over the world. With innovative technology comes many great benefits. CNC machining has become business owners’ go-to when they want to create prototypes or manufacture hundreds of the same parts. Business owners are provided with a much quicker and more accurate manufacturing process than in the past.

This process comes with a price. Instead of purchasing your own CNC machine box or Computerized Numerical Control machine, you can rather invest in a professional prototype machining company to run your project. Machine shops have a professional and qualified team that are able to operate machinery and ensure on-time delivery with precision.

Not only will you be saving a lot of time, money, and effort, you’ll also receive high-quality products from experienced professionals. Not convinced? Here is a list of all the benefits of hiring a professional to undertake your CNC machining project.

Quick as a Flash

Hiring a machining company to help you produce your first prototype will save you a lot of time. A quick turn machine shop have specialized equipment and skilled professionals who will be able to produce a prototype within a few days. Sometimes the prototype can even be delivered within a day.

Compared to hiring manual machinists who need a lot of time, you’ll have a much more precise product within a jiffy.

Since most machine shops use highly intelligent technology, they’ll most likely have a tracking system too. This will allow you to track big orders that are almost always guaranteed with an on-time delivery rate.

Customizable Services

The greatest advantage of using a prototype machining company is that they can provide you with customized products. This will come in handy when you are trying to create prototypes that are ahead of the competition and innovative in nature.

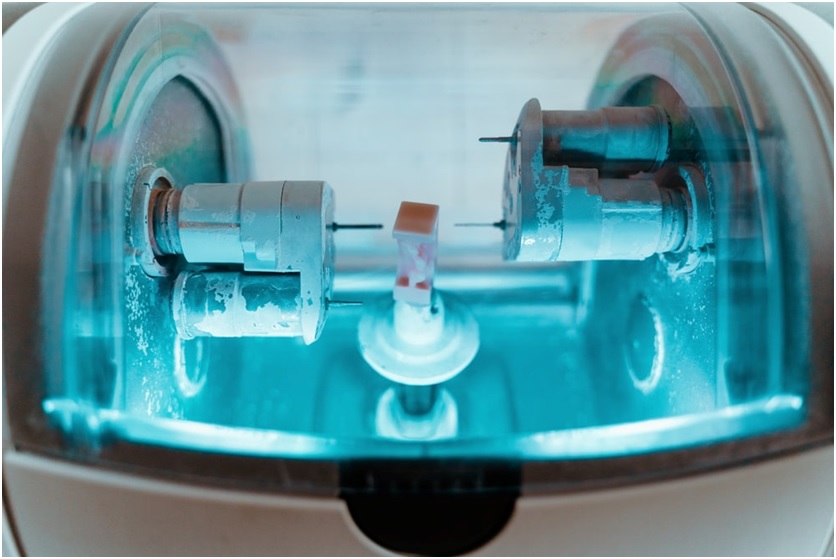

Together with the shop and operators, you’ll be able to manufacture a variety of parts in different shapes and sizes. Latest software allows CNC machines to perform precise milling, drilling, and machining.

Avoid Human Error

If you send your prototype project to a manual machine operator, you’ll not only have to wait much longer but the chances of something going wrong is much higher too. Because manual labor requires someone to drill and chisel away at a stock of material, they might chop off too much and will have to start over.

Compared to a CNC machine that is computer operated and won’t make any mistakes.

High Level Precision

Another reason why business owners are turning to CNC machine shops is because they are extremely accurate. Technicians input the G-code into the processor and observe the machine create accurate cuts, drills, and mills.

The entire process is automated, which means that human error is completely avoided leaving the machine to achieve high levels of precision.

Most CNC machines have precision readings of up to one thousandth of an inch. This accuracy also allows for precise repetitive cuts when creating more than one prototype with the same specifications.

Trained Professionals

If you are considering purchasing your own CNC machine for your business, you are going to have to either train your employees to operate the machine or hire someone who can specifically operate it.

Trained professionals within a shop have the required experience, skills, and expertise to operate different types of CNC machines. Another great advantage is, that you’ll be working hand-in-hand with one operator who will know all the ins and outs.

Communicating with one operator instead of many different technicians will ensure that the project runs smoothly.

Material Options

Depending on your project, you’ll be able to request any kind of material ranging from strong metals to plastics. In many cases, business owners use 3D printers to make prototypes. Regardless of their accuracy, 3D printers can only use a limited number of soft materials.

You’ll be able to request prototypes of powerful steel and aluminum as CNC machines can cut through almost any material. Most shops will also have a variety of different materials in stock that you can choose from. Technicians will be able to advise you on which materials are suitable or whether there are any alternative options.

Less Waste of Material

Because most prototype creation processes use a cutaway technique, a lot of waste material is created. Human error will also create a lot of waste, which will incur higher material costs.

CNC machining is extremely accurate. When creating a series of parts, the machine will minimize wastage by creating optimum usage of materials. Watch this to witness how CNC machining works in reality. Machine shops can even use some wastage to recycle or melt together to create new sheets.

Furthermore, material is bought in bulk. Which saves you a lot of money when ordering hundreds of parts.

Convenience

Hiring a machine shop to create sets of parts is extremely convenient. You won’t have to rent a space to store your own equipment and materials, as you can use all the facilities provided by the professionals. In some cases, your project might need a specific CNC machine or cutter. Investing or purchasing your own can be expensive and will open up another set of organizational elements that can be avoided. Rather let your team focus on designing digital prototypes and G-codes that machine shop technicians can turn into a reality.

Using technicians from another company will also give you the opportunity to build report for any other future projects. Having a great relationship with a shop will create a smooth process and even increase your brand awareness.

Conclusion

If your business is looking into creating specialized parts and prototypes, then hiring a professional prototype machining company is definitely worth the investment.

Make sure that you hire a machining company that is up to date with the latest machining software and equipment. This will ensure that they meet all your specific requirements.

Improve workflow, increase production speed, create accurate parts, and enjoy the benefits that comes with hiring a machining company.