Everything You Need to Know About Industrial Castings

The importance of investment castings is immense. It is a solid waste material that is formed from waste materials that are disposed of in the normal course of business. The industries, plants and houses which make use of castings are able to benefit from a number of benefits. They are not only desired for their useful properties like recycling and sinks, but also for their aesthetic and financial qualities.

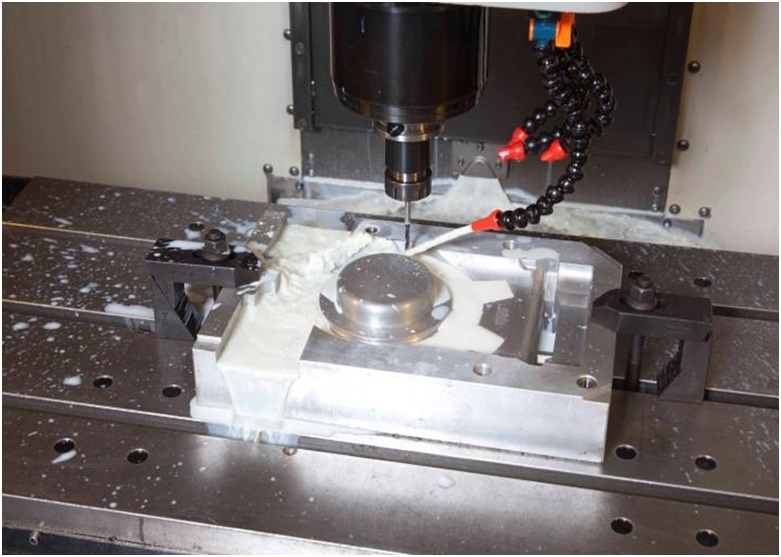

The waste castings from industries like cement, mining, pharmaceuticals, petroleum, paper and pulp mills are usually rich in nutrients and minerals. They can improve the productivity of these industries a great deal. Apart from this, they are a cost-effective alternative to most other means of recycling. These castings are the perfect replacement for many chemicals and waste management options. They are environmentally friendly as well because they are made from ash left over from the burning of fossil fuels. The investment casting surface roughness process is known to yield great results.

How are investment castings important?

The castings from industries that use them are considered biodegradable and therefore safe to use. This is because when the process of digestion of these castings is carried out, no hazardous gases are released. This is also one major benefit that most people are unaware of. It means that the castings are useful for both the environment and the industry.

Another important advantage of the castings is their ability to increase the soil fertility. They are rich in nutrients and are known to act as a natural fertilizer. This is a definite benefit for the farmers who depend on them to increase the productivity of their fields. Castings can also be used for beautification purposes. They are usually used for beautifying parks, beaches and recreational areas.

Many industries also use castings as a form of recycling. As they are highly non-toxic, they do not require any complex processing. They are also highly eco-friendly as they contain no hazardous chemicals that may prove harmful to the environment. Therefore, industries are making the most of the castings for waste management and also as an eco-friendly material for making other products as well. There is no question that this is a great way of recycling waste and is one way of saving the environment from further pollution.

Apart from the many advantages that this waste has to offer, it has some important drawbacks as well. One of the biggest disadvantages of using this material in waste management is its inability to resist adverse weather conditions. Although they are resistant to weather and other environmental factors, they are not able to withstand extremely harsh weather conditions. For instance, they are unable to hold up under cold or heat, and they become useless.

The castings are also used for water purification. As they have high water solubility levels, they are capable of effectively removing toxic elements such as heavy metals, volatile organic compounds, and other contaminants from water. These castings have the ability to reduce the contamination levels in the environment by reducing the amount of time needed for the removal of these contaminants. This is a definite advantage as it helps to ensure that waste is kept safe from harm and is therefore pollution free.

Most people do not realize the importance of casting until they experience some problem with it. The waste that people will produce every day is cast off without giving it a second thought. In fact, the majority of people are so used to throwing away waste that they have completely forgotten about castings. It takes them a while to realize the benefits of castings when they are surrounded by waste. However, once people start realizing the importance of castings in waste management, then they will realize the need to protect this material and start using it more often.

There are a few ways in which this material can be made more eco-friendly. Since the waste does not contain valuable minerals that are needed in the manufacturing of new products, it is possible to make castings out of the leftover material. This would allow manufacturers to utilize the best possible raw materials without consuming them unnecessarily. Therefore, by using castings, the amounts of natural resources that are required for the manufacture of new materials can be minimized. In addition, it can reduce the cost of maintaining the manufacturing industry since the amount of energy and water used for processing purposes will be much lower.

Final Take

It is obvious from the above discussion that the importance of investment castings in waste management cannot be ignored. In fact, it can be considered as a very important component of waste management. By using the waste castings, it is possible to improve the quality of water and reduce the cost involved in maintaining the waste stream. Therefore, investment castings can play a major role in the proper functioning of waste management and can improve the environment in the most beneficial way.