Five Things To Know About Crimping Machines

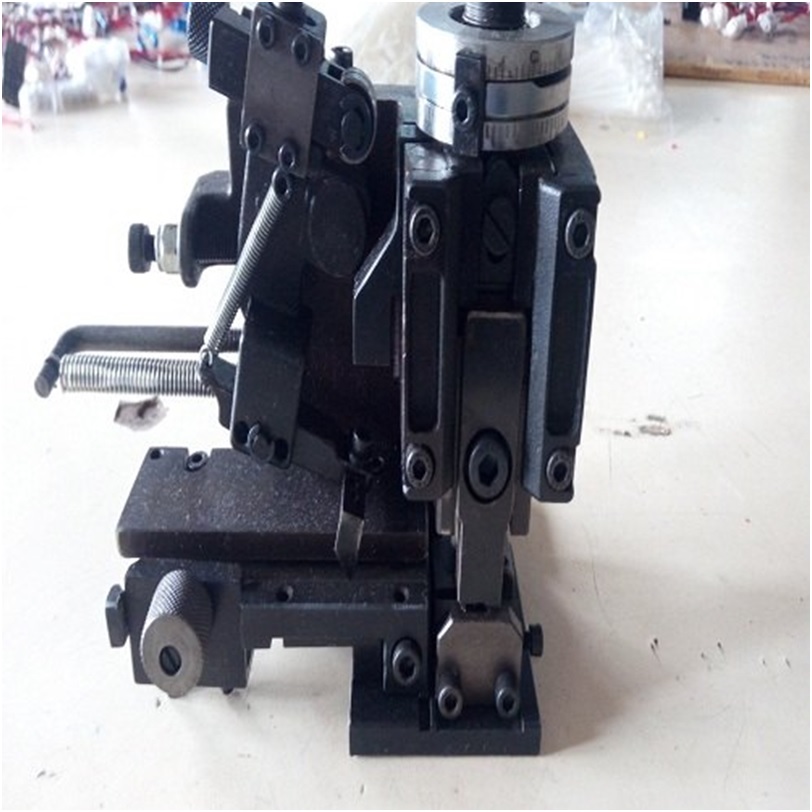

An automatic crimping machine is a tool used to process wires by stripping, crimping, inserting, testing, and through an auxiliary process that prepares the wire for harness assembly. As the wire processing equipment is in great demand in the marketplace, automatic crimping machines have a clear lead. It helps the manufacturers improve productivity and cut down production costs.

Finn-Power industry is a leading manufacturer of the best quality crimping and cutting machine tools. You can learn about Finn-Power India from its official website. Known widely for its quality and durable crimping machines, it is the most significant services provider as well as a stockist of general production machinery in the country.

Purchasing a wire crimping machine is a long term investment for your industry. It can be the ideal solution for high-speed wire processing. From cutting, stripping, crimping, sealing, twisting, and tinning, your crimping machine can be put to multiple uses. It can improve the cost per lead for a wide range of applications. Suppose your wire harnessing industry is involved in the production of wire harnesses with terminals and connectors. In that case, you can purchase the crimping machine to process it at high speed and high accuracy.

However, before you make your purchase, you need to have a clear understanding of the various features of a crimping machine. Here is a list of five things you need to know about a crimping machine to make a better purchase.

Five Things To Know About Crimping Machines

-

Understand Your Production Volume Statistics

To better understand the potential suppliers of a crimping machine, you can conduct a quick internet search. This will help you know what the suppliers offer, and you can also analyze which one will suit your needs better. Many variants of crimping machines are available online, ranging from semi-automatic loose-piece crimping to fully automatic measure, cut, strip, and terminate which can be customized to suit your industrial needs.

How do you choose a crimping machine that is suitable for your industry? You need to run a production analysis for the various work segments to understand how many crimps each segment requires. After you determine the quantity required, you can contact a specialist in this domain to find the price variations between semi-automatic and fully automatic machines.

-

Understand Current And Future Applications

Various industries like automotive, military, and aerospace require continual product innovation. As the products continue to evolve, the change in the configuration increases the wire harness requirements. The changes in the application also affect future product requirements. The flexibility of the automatic crimping machine becomes a determining factor for any manufacturer. Customers should have a visionary approach to understand how the crimping machine will meet their industrial needs in the future to remain functional for a longer-term.

-

Choosing The Right Supplier

While purchasing any capital equipment, the customers should have better technical support service. As a customer relies on one fully automatic crimping machine for most of their production needs, in case there is an anomaly in the functioning of the machine, ready technical assistance should be available. Some of the crimping machine suppliers train and certify their technicians covering all the products, while other suppliers train them for a specific category. You need to understand the terms and protocols of their service.

-

Quality Assurance

Reducing unnecessary scrap materials helps to reduce the cost. Some software helps distinguish the inaccuracy in the strip lengths, finds the missing strand, and determines the crimp height and insertion depth. This helps to reduce the faults in wire processing and brings down the manufacturing cost. Monitoring the crimp force helps to detect false crimps during the production stage, which eventually supports quality assurance. With this, the faulty cables can be sorted out, ensuring that such faulty cables are not used in the downstream process.

-

Robustness And Durability Of The Product

You need to identify the strengths and weaknesses of the crimping machine and should not rely on the marketing messages that the supplier sells to you. The robustness and quality of the machine should be tested. A robust crimping machine ensures high durability and reproducibility of the crimp connection.

To Conclude:

An automatic crimping machine is a long-term investment that will cater to your wire harnessing needs. To make a better purchase, you should understand its current and future applications that should be concurrent to your business needs. It should be able to handle wires carefully, gently during processing. You need to choose the right supplier of the crimping machine for quality assurance and greater reliability. A powerful and durable machine reduces maintenance costs and enables a better productivity performance due to a synchronized machine setup and operation.